Today, more power plants are built, therefore, the application of refractory materials is more and more important.

Drying Refractory is critical for strong, long-lasting refractory applications. Unfortunately, standard refractory dry-out schedules, provided by all refractory manufacturers with their products, are difficult to apply to refractory used on a steam-generating boiler. CNBM could realize this, because we have the most authoritative Academy in China- China Building Material Academy.

These standard dry-out schedules are generic and require temperature monitoring rarely found at power plants, where monitoring capabilities are limited. Power plants monitor what is important to maintain their boiler operations: boiler exit gas temperatures, air temperatures into the windbox, steam drum temperatures, and steam outlet temperatures. They do not specifically monitor the temperatures where they have refractory. Thus, the dry-out schedules for drying refractory used on boilers must be tailored to the plant\'s temperature-monitoring capabilities, and need the engineers have much experience in this step. CNBM’s engineers have more than 20 years experience in the drying work. They always guide the installation for 24 hours.

Refractory is used on all steam-generating boilers. Its primary function is to close and seal all openings or gaps so that the fire, heat, gas, and fly ash will not escape the confines of the boiler. So that if the drying work is not done well, it will affect all the boilers.

Regardless of boiler type, refractory applications are similar, such as refractory-filled wall boxes, refractory on tube walls in non-membrane areas, and at least one large refractory seal somewhere inside the boiler. For a radiant-type boiler, there is usually one such large seal at the top of the super heater floor just before the convection or heat recovery area. This is usually where the screen tubes are located, so the seal is sometimes referred to as the screen seal. Figure 1 shows a typical radiant membrane boiler.

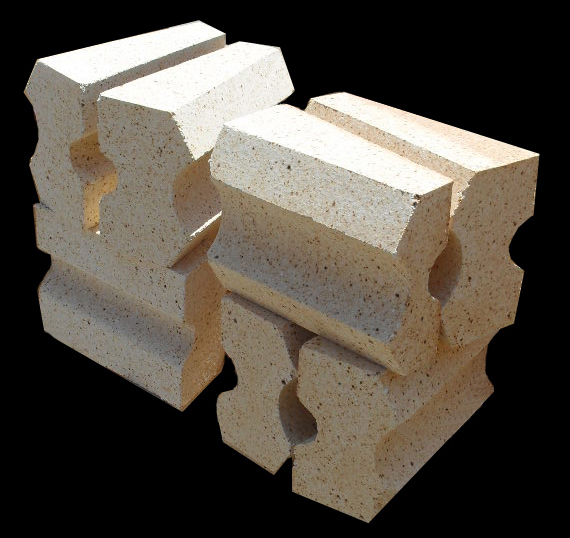

The most common refractory materials used throughout the power industry for sealing and closing gaps and openings are cement-bonded, medium-weight materials, sometimes referred to as conventional-type refractory. They are the materials of choice because of their versatility and cost (about half what a specialty-type refractory such as silicon carbide or high alumina refractory might cost). Like all refractory materials, they must be properly dried to achieve their designed strengths.

Dry out, also referred to as bake out, is the process for removing both the mechanical water (added during the mixing process) and chemical water (originally added in manufacturing) from the refractory. Dry out must not be confused with curing, which is the process of keeping the refractory material wet or the surrounding atmosphere humid for 24 hours prior to applying heat for drying. This curing process is required on all cement-bonded refractory to create the most favorable conditions to complete the chemical reactions of the cement and water.

The heat source for the drying of the refractory is the boiler itself. The drying is done during the initial start-up of the boiler. While refractory manufacturers have their own recommended dry-out schedules, most all agree that a slow ramp rate of the heat is required to protect the undried refractory. The recommended ramp rate ranges between 50oF and 100oF. The first hold point is the most critical for cement-bonded refractory for removing the mechanical water and is usually between 220oF and 400oF. The mechanical water is turned into steam and forced out of the refractory by the heat. The upper hold points remove the chemical water and form the final bond within the refractory for maximum strength.