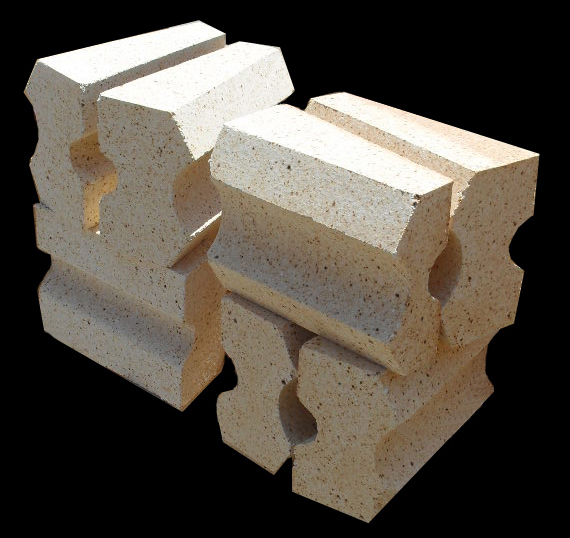

What is Insulating Fire Bricks?

Now more and more furnace use insulting fire bricks as the back wall and even hot wall. What is insulating fire bricks? Why they use the insulating fire bricks to instead of parts of the heavy bricks?

Due to the heat loss of the surface of the furnace and the thermal storage of brickwork, the fuel was wasted from 24%-45% before. The insulating fire bricks have the advantages of lower thermal conductivity and less thermal capacity. If we choose the insulating fire bricks for furnace, we could save the fuel. Meanwhile, the furnace could be heated up and lowered the temperature rapidly and increase the productivity. And the insulating fire bricks could reduce the weight of the furnace ,low the temperature of the workshop and improve the work condition.

But insulating fire bricks also have its’ own disadvantages. The loose and porous insulating fire bricks are easy to be invaded by slag and broken. So the insulating fire bricks couldn’t contact the slag and liquid metal directly. Meanwhile, the insulating fire bricks have low strength and not good at wear-resistant and thermal shock resistant. So the insulating fire bricks couldn’t be used us bearing structure and the used in the place suffering heavy wear.

Due to the advantages and disadvantages, the insulating fire bricks are mainly used for back wall, lining and insulating layer and not for the place which contacting the furnace charge and slag directly.

There are four methods for the manufacturing of insulating fire bricks. The details are as below:

1.The first method is burning out the addition, which is also named combustible materials. For this method, the adobe of the insulating fire brick will be added combustible materials, which is easy to be burned out, such us the charcoal powder, sawdust, etc. After burning, these combustible materials will make the bricks have porosity.

2.The second method is foaming method. The casting slip will be added forming agent, such us rosinate soap foamer. Then the casting slip will be bubbly by mechanical method and finally get the porous insulating fire bricks after burning.

3.The third method is chemical method. In producing, people usually use the dolomite or periclase and gypsum, and sulfuric acid as the forming agent. These materials will create gas by their chemical reaction. Finally, we also could get the porous insulating fire bricks.

4.The forth method is porous raw materials. The insulating fire bricks also could be produced by natural diatomite, alumina bubbles, etc.

The main insulating fire bricks are fire clay insulating bricks, high alumina insulating bricks, mullite insulating fire bricks, silica insulating fire bricks and alumina bubble insulating bricks.